Application : FFB, SFB, boiler ash, fiber conveyor and other conveyor station

Welding of ferritic and austenitic material and stainless steel to carbon steel, cast steel, low alloy steel, rebuilding of shaft, wall surfaces, turbine blades, impellers, steel mill rollers

An ideal electrode with outstanding weldability for welding of nodular cast iron malleable cast iron, grey cast iron arcs where high strength and ductility are required and yet deposits must be machinable. Welding of engine blocks, cast iron gears, sliding tables, cylinder heads & heavy machine base. Outstanding feature of this electrode is that it will have minimal base metal penetration and dilution.

For hard facing of part subjected to severe abrasion accompanied by impact, fibrizer hammers,augers, screws, conveyors, scrappers, blast furnace bells, hoppers, press worm screw & EFB press.

Metal surface coating for protection against high temperature oxidation and corrosion.

Ceramic Putty gives a very hard and abrasion resistant surface due to its extreme scratch resistant property. This hard surface protects the applied area from erosion and corrosion.

Titanium Putty provides a high performance, metal filled epoxy for long term solution and allows for machining.

Ceramic Coat gives a very hard and abrasion resistant surface due to its extreme scratch resistant property. This hard surface protects the applied area from erosion and corrosion. The raw materials used in this formulation are of pharmaceutical grade, ideal for food industry.

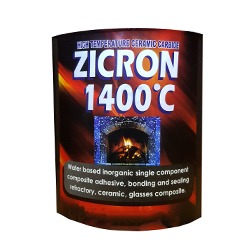

Water Based, Inorganic, Single Component Composite Adhesive. Bonding and Sealing Re-factory, Ceramic, Glass, Metal, Composites etc. Eco Friendly. No VOC Content. Non-Toxic. Stable up to 1400 °C in Air and Inert Atmosphere

Application : Power Plant, Coal Mining and Palm Oil.

Hardness : 70 – 72 HRC